Our modern video analysis tool helps production managers, factory managers, Lean specialists and persons responsible for Continuos Improvement Processes who face the difficult task to identify and optimize inefficient prozesses and consequently to reduce costs considerably. Therefore the video analysis is an efficient tool, with which you can identify potentials and develop measures for process optimization.

Using the TimeStudy video analysis you can track unproductive processes and optimize them systematically and with simple but effective measures.

Special advantages of the video analysis:

- the production is not disturbed

- cameras record the reality – in case of need even in slow motion

- the videotaping can be repeated any time – therefore all processes are documented and reproducible

- mounting processes can be analysed in detail and so finally be optmized

- a multitude of reports is available – e. g. value added analysis or templates for work instructions

The modern software is easy to use and simplifies the data collection and evaluation significantly by:

- high accuracy of process measurement on the computer by precise image adjustment

- any repetition of sequences and number of measurements and the possibility of individual evaluation of each section of the data flow

- direct retrieval of individual video sequences by using the stored start and end times of each section of the data flow

- convenient processing of the results into standard spreadsheets, such as Excel, fulfilling the requirements of REFA (epsilon value, evaluation of the performance rate, cover page with recording data, etc.)

- possible subsequent anonymisation of the filmed persons

- support of all common formats, for example wmv, mp4, Quicktime, AVI and mpg – more on request

Kaizen, Continuous Improvement Processes, Six Sigma

With the video analysis you get a solid database, which is more than just a simple time recording:

- effective basis for the identification of optimization approaches together with all relevant employees (Continuous Improvement Process, Kaizen, Total Quality Management)

- by entering various parameters (such as production volume, investment costs, expected potential efficiencies, etc.) the potentials and the amortization period of necessary investments are calculated directly from the video analysis module

The search for productivity potentials sometimes is not so easy. But our experience shows, intelligently used video films lead to improvements of a remarkable percentage.

Integration of staff and works councils

The video analysis has got a high potential as pictures tell you more than 1000 words. Consequently you do not have to discuss anymore what everyone thinks to see but what actually happens. The integration of staff in the preparation process and the analysis of the video as well as in optimization workshops ensures the acceptance of the measurements found, even with the works council. In many cases the ergonomic advantage and economic value is an advantage for both – the employees and employer.

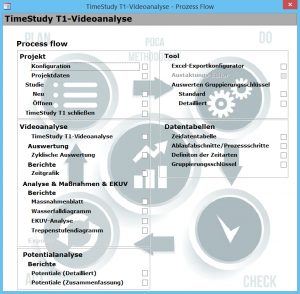

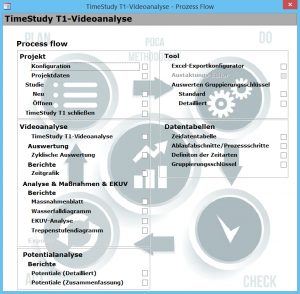

The TimeStudy video analysis offers an easy navigation by a Process Flow.

Besides the video analysis offers a potential analysis, the determination of standard times and also the possibility to create instructive films.

At the same time such an optimized process, supported by visual work instructions, is also optimizing the product quality, as error rates drop and training times are reduced. Often there is also additional information for the development in order to increase productivity and quality.

Learn more